Network technology, communications, and data will be strategic factors as mining companies strive to be more profitable. With key drivers being productivity and safety, modern network connectivity, communications, and intelligent use of data has the potential to bring huge benefits.

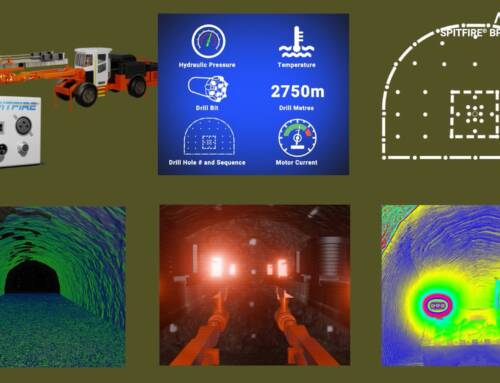

Nautitech's resident R&D Engineer, Dr Douglas Carter recently presented the importance of investing in connectivity and communications at the Future of Mining Conference in Sydney. As he explained it, communications networks have become central to mining as they allow us to collect valuable data from the entire mine site. With the use of sensors and the information provided by historical data, every aspect of the business can be improved from control and maintenance of machinery, worker safety, to increased productivity and autonomous operations.

The underground mining industry has evolved from the use of simple tools such as pick axes in its infancy to the complexity of a modern-day longwall system. Network capability and reliability have seen huge gains in remote areas and underground, particularly in the past decade, although underground coal mining has been slower to adopt network technologies, largely due to the presence of explosive atmospheres and stringent standards for worker safety.

NETWORK CHALLENGES BY MINE TYPE

There is no single technology that is a best fit in all the categories that matter for mining. While fibre is generally best for high volumes of data to be carried over large distances, this can prove to be challenging in underground operations where there is a significant amount of machinery and personnel.

BEST FIT NETWORK TECHNOLOGY

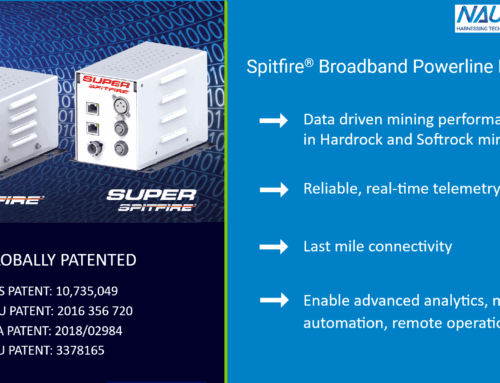

Fibre connections from the surface to the face are reliable but prone to failure as conditions at the face are particularly severe. The best solution is high speed power line technology that transmits data over the existing power cable which is capable of withstanding the hazardous environmental conditions.

A hybrid network requires fibre technology from the surface to the point of entry to the underground mine section while a power line network continues the link to tethered vehicles and machinery, allowing operational data to be transferred to the surface.

While the importance of data collection is indisputable, less than 1% of data collected by mining companies is used and "data noise" makes it difficult to see the value.

The CSIRO estimates that simply using data more effectively can make a business 6% more profitable, which is considerable, given the scale of the mining industry. Data should be treated as a strategic asset which could potentially save billions of dollars in operational costs, as well as improve worker safety and increase productivity. Historical data can be used for preventative maintenance, simulation, operational planning, predictive insight into production levels and asset management.

Pressure to lower commodity prices, higher operating costs, stringent safety standards, complicated legislation, and complex mining areas create a viable opportunity for mining companies and support industries to invest in and make better use of network technology, comms and data.

Read more here about the Spitfire BPLM solution which sends data over the pilot cores and power cores of existing trailing cables.

For more information, contact Nautitech at: