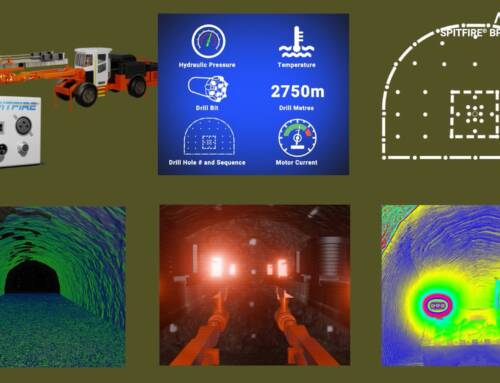

Efficient, productive, high quality coal extraction during development operations relies on marker band identification for creation of a development panel heading. But identifying these markers with the naked eye can be challenging as visibility and safety of a miner driver may be affected by dust, water, mine site terrain, and insufficient illumination.

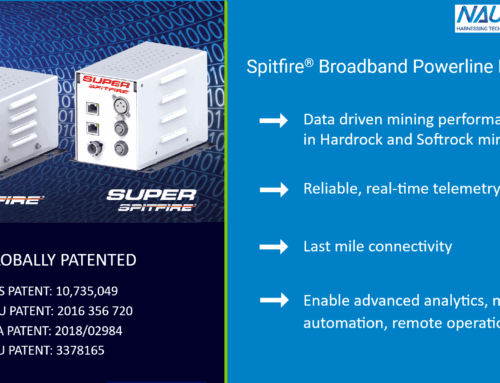

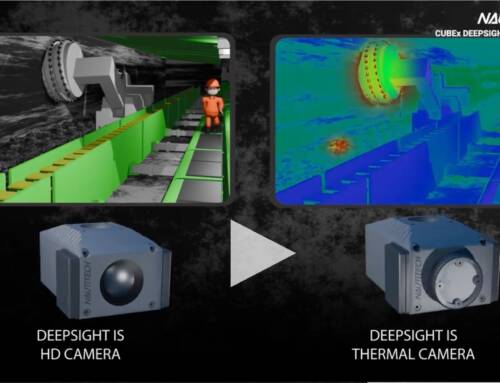

These limitations can be overcome by using a thermal camera to identify marker bands which have a distinct visual aspect and are reliably positioned in the coal seam. The Nautitech® thermal camera with ONVIF, paired with a Spitfire® BPLM can help mine sites achieve maximum productivity in a safer environment – a fundamental aspect of our product design.

Utilising ONVIF data compression, the Spitfire® BPLM can transfer thermal images of the coal seam, which can be used to identify areas with high quality coal and used for remote monitoring of the continuous miner for maximum productivity and a reduced risk to mine workers.

For additional information about the Nautitech® ExTREMECAM Thermal Camera with ONVIF and the Spitfire® BPLM, call us on (02) 9899 6857, email or visit https://www.nautitech.com.au/