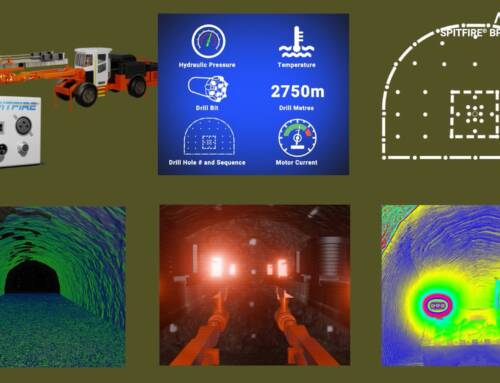

Longwall operations are one of the most challenging areas of underground mining – and equipment installed on Shearers, AFCs, Roof Supports and BSLs has to withstand the same punishing conditions that these behemoths endure.

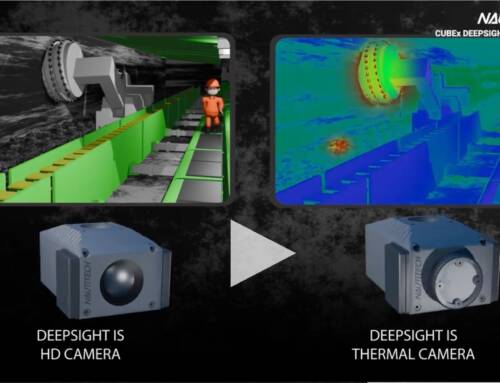

Complexity of the terrain, vibrations, and hazards not always visible to the naked eye make Longwall mining one of the most difficult environments to work in. To ensure that Nautitech® Lights, Cameras and Communications systems survive tough underground conditions, they go through stringent factory acceptance testing (FAT) which includes:

- Robust design

- Identifying technical and safety risks

- Preparing a detailed FAT plan

- Test procedures that replicate underground conditions

- Rectifying issues on component, assembly, and system levels

We firmly believe that it’s best to resolve an issue before it leaves our manufacturing facility as it may cost 10 times more to correct it on the surface and 100 times more once installed underground.

The robust design, rigorous testing and methodical production translate to products that can withstand the harsh environments of underground mining between overhauls and beyond.

To learn more about Nautitech® products, call us on (02) 9899 6857, email or visit us at nautitech.com.au