Real-time Connectivity in Hardrock Mining

Watch the video HERE

When it comes to hard rock mining, real-time connectivity is a key consideration for safety and output efficiency in a profitable mine. As mining equipment advances deeper into the mine, reliable “last mile connectivity” can be challenging.

Communications Networks

Mine site communications networks such as Fibre, WiFi, 5G, and Leaky Feeders are dependable options for fixed infrastructure. But for that last section of mine – at the point where production begins:

- Fibre is not practical enough for production and development environments

- Poor line of sight makes reliable connectivity a challenge for WiFi and 5G

- Leaky Feeders are primarily designed for voice, not typically used for data

Many mines do not have the ability to receive real-time data from production and development drills, as it is relayed to the mine control room on the surface after the shift ends. Data is usually transferred via memory stick or transmitted by a machine reversing to a WiFi access point.

Latency Issues

To address the latency associated with data transfer, the NAUTITECH® Spitfire® Broadband Powerline Modem offers an extremely dependable high-bandwidth communications solution that utilises machine trailing cables without any additional mine infrastructure.

By using trailing cables, the BPLM can be directly integrated into jumbo drills overcoming any signal deficiencies experienced by conventional communications networks.

In fact, the globally successful Spitfire® BPLM has overcome the issue of “last mile connectivity” on thousands of machines in soft rock mines which depend on real-time data for automation and remote operations.

The advantages of real-time connectivity and data transfer are substantial.

Consistent data and video output from the Spitfire® BPLM, when installed on a production or development drill, can facilitate continuous operations even during shift changes and crib breaks – significantly increasing mine productivity.

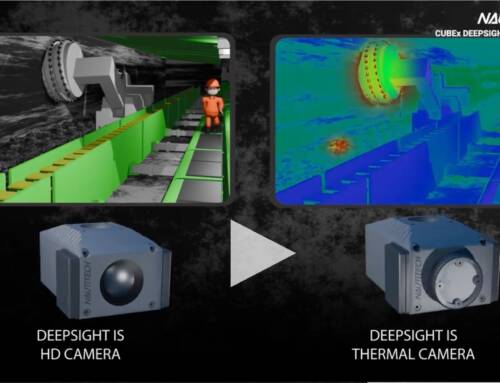

The Spitfire® BPLM can transmit machine telemetry, bolting patterns, lidar mapping, visual streaming, and thermal imaging. It can also signal breaches in proximity awareness systems. This information can help streamline the drill and blast process and ensure safe operations. Additionally, communication to the workshop can be instant – minimising down time and improving maintenance response times.

The Spitfire® BPLM has established itself as a reliable connectivity platform that promotes automation, data analytics and remote operations. Its performance has consistently exceeded expectations making “last mile connectivity” very achievable for hardrock.

Reach out to NAUTITECH or Digital Terrain, our partner in Australia, to find out how Nautitech harnesses technology to keep miners safe.

Contact Digital Terrain – for Australian sales of Spitfire BPLM for Hard Rock

For global enquiries about Spitfire BPLM for Hard Rock, email