Nautitech and Swanson Industries recently collaborated on a test to establish data transfer between the DCB and Swanson’s shuttle cars, affectionately known as Waracars.

The objective of the test was to determine speed and quality of communications from shuttle cars and any influencing factors caused by slip rings on trailing cables as they are wound or unwound. Swanson and Nautitech engineering staff came together at a surface workshop in Argenton NSW with both parties providing the following equipment:

From Swanson

- DCB

- Shuttle Car

- Trailing Cables in two lengths: 90m + 267m

From Nautitech

- Spitfire® Broadband Powerline Modem (BPLM)

- Capacitive Couplers featuring insulation suitable for system voltages up to 7.2 kV in accordance with IEC60071-1

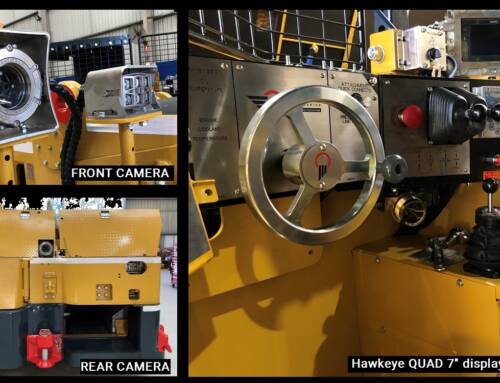

- Remote displays installed on the Shuttle Car and the DCB

Operational statistics were gathered using AVitar software and payload data rates were measured using iPerf. The Shuttle Car was put through its paces and data transfer was tested in idle mode, as well as forward and backward movement using the trailing cables individually and connected together to gain a greater distance.

Key findings from the test:

- Data was successfully transferred at a rate of 20 Mbps in both directions from a moving machine

- Clear data transfer was achieved on individual trailing cables as well as a combined distance of 357 metres

The Nautitech Spitfire® underground broadband communications solution has great possibilities for use on other machinery that uses a trailing cable as a power source. Trials of the Spitfire® BPLM solution in Australia and the US show highly positive results, with enough data throughput for reliable real time operational monitoring, and enough spare bandwidth to transfer video data for machines fitted with HD or Thermal cameras.

Applications such as Shuttle Cars, Feeder Breakers, Ventilation Fans, and Proximity Detection Systems can be networked to transfer data and video from the local system to the surface. Such valuable information provided to the mine control room in real time will no doubt offer additional opportunities to drive improvements in safety, efficiency and productivity.

Read more here about the Spitfire BPLM solution for Communications in Underground Mining.